Guide to coal plant demolition

Several factors are fueling coal plant demolition in Australia and across the globe. With the shift towards renewable energy resources, recent caps on greenhouse gas emissions, and extra wastewater regulations to consider, an increasing number of coal-fired operations are proving non-viable.

But how can you demolish a coal plant efficiently, recover valuable scrap metal and preserve the land for redevelopment?

To achieve these goals, the demolition of a coal plant must be approached with extreme diligence and care. This complex process involves multiple stages, from decommissioning, safety assessments and hazardous material abatement to dismantling, waste removal and site remediation.

It’s vital that plant owners understand the strategies, documents and risks of each of these milestones. That way, it is possible to protect the plant’s workers, community, surrounding environment and reputation.

Below, we explain the core steps to successful coal plant demolition. Keep reading to discover the key preparation and administrative duties of plant owners and demolition contractors throughout this high-stake project.

Coal plant decommissioning

The first step is to decommission the coal plant. This involves notifying all personnel of the closure, shutting down operations and getting rid of any in-process or raw materials.

As the plant owner, you may also choose to sell certain assets, such as electrical generating equipment, on the scrap market to recoup the investment. Additionally, you can also sell the land to a property developer or other organisation at this stage for redevelopment.

Assessments and planning

The next step is to examine the structures to be demolished and the land on which they stand. Performing in-depth risk assessments is crucial to flagging and mitigating all potential hazards before coal plant demolition takes place.

As well as protecting the community and informing the demolition plan, these reviews will help to ensure your project abides by environmental legislation and national safety standards.

Pre-demolition assessments typically include:

- A site survey to analyse environmental risks and confirm the scope of work required.

- An engineering assessment to determine structural integrity, design and relevant building codes. These insights will help to pinpoint the most appropriate method of coal plant demolition.

- An electrical assessment to clarify the power supply across the site, as well as any isolation needs.

- A fire assessment to check for flammable materials and confirm the fire prevention and control measures required throughout decontamination and demolition.

- A work health and safety assessment to identify potential dangers to personnel and develop suitable protective and emergency protocols.

- A hazardous material (HAZMAT) inspection to verify the nature and location of hazardous materials, such as asbestos.

Equipped with the above findings, your contractor will prepare a detailed demolition plan that covers all key project details, including the:

- Location of the target structure;

- Any structural support systems;

- Distances between this structure and nearby buildings, infrastructure and public spaces;

- Method of demolition and the series of tasks to be performed; and

- Project timeline and estimated completion date.

It is also important to implement other plans, such as a Health & Safety Management Plan, Waste Management Plan and Environmental Management Plan. These strategies should detail the procedures needed to carry out your project in line with relevant legislation and the demolition contractor’s integrated HSEQ management system.

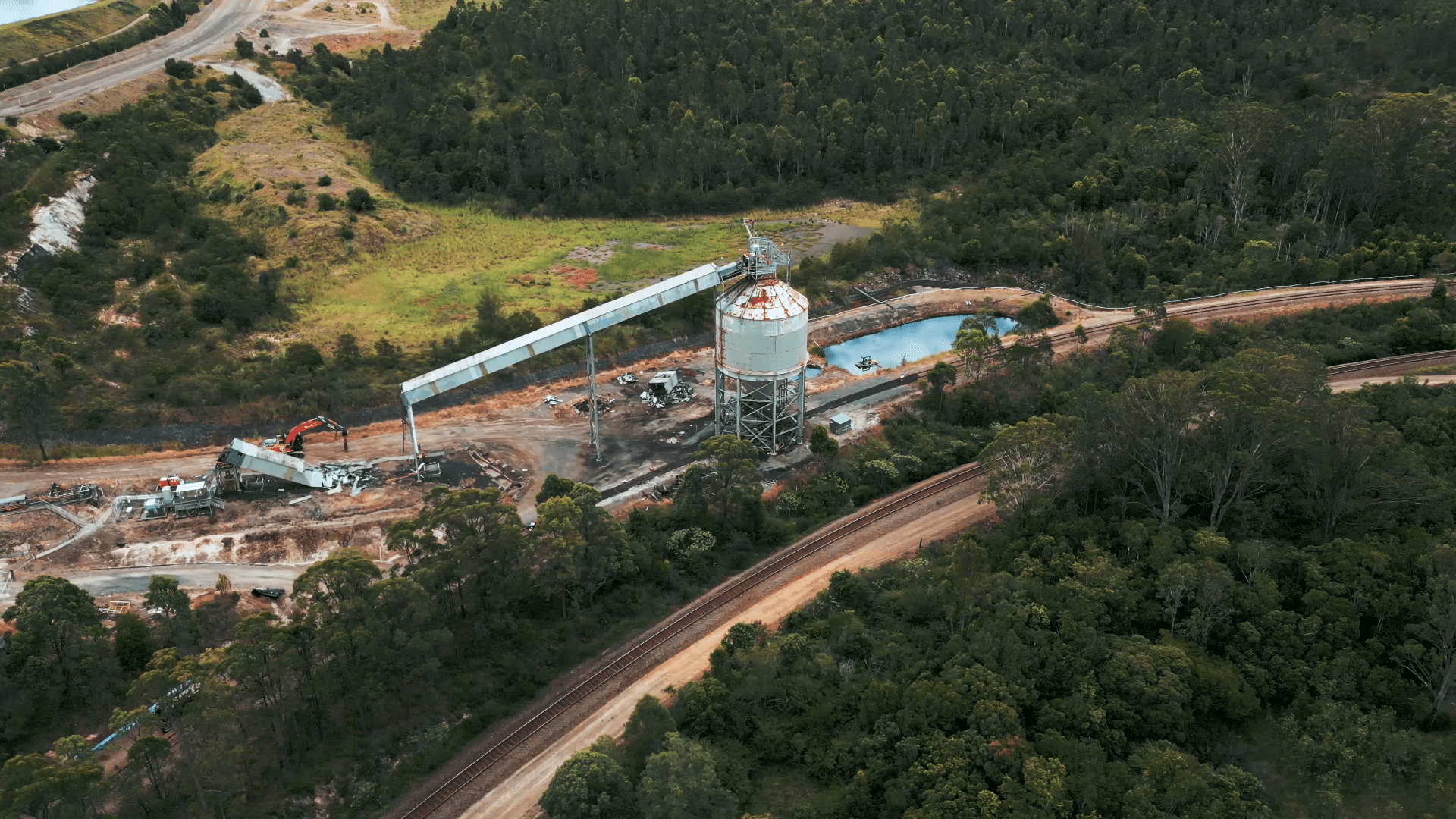

Mach Energy Conveyor Demolition

Hazardous abatement and remediation

Moreover, if the site is intended for redevelopment after demolition, it must be free from harmful contaminants and therefore qualify for a Clearance Certificate – which is necessary for any construction down the line.

Therefore, it’s important to budget for hazardous material assessment and removal services, as well as add an appropriate buffer in the overall project timeline.

With a Class A (Friable) Asbestos Licence in the majority of Australian states and territories, Major Projects Group draws on over 40 years of industry experience to provide unparalleled asbestos and hazard material removal services for coal plant demolitions.

We partner with expert subcontractors to utilise state-of-the-art resources that maximise efficiency. Our end-to-end solutions include inspections, testing, air monitoring, abatement, encapsulation, disposal, waste management, consulting and more.

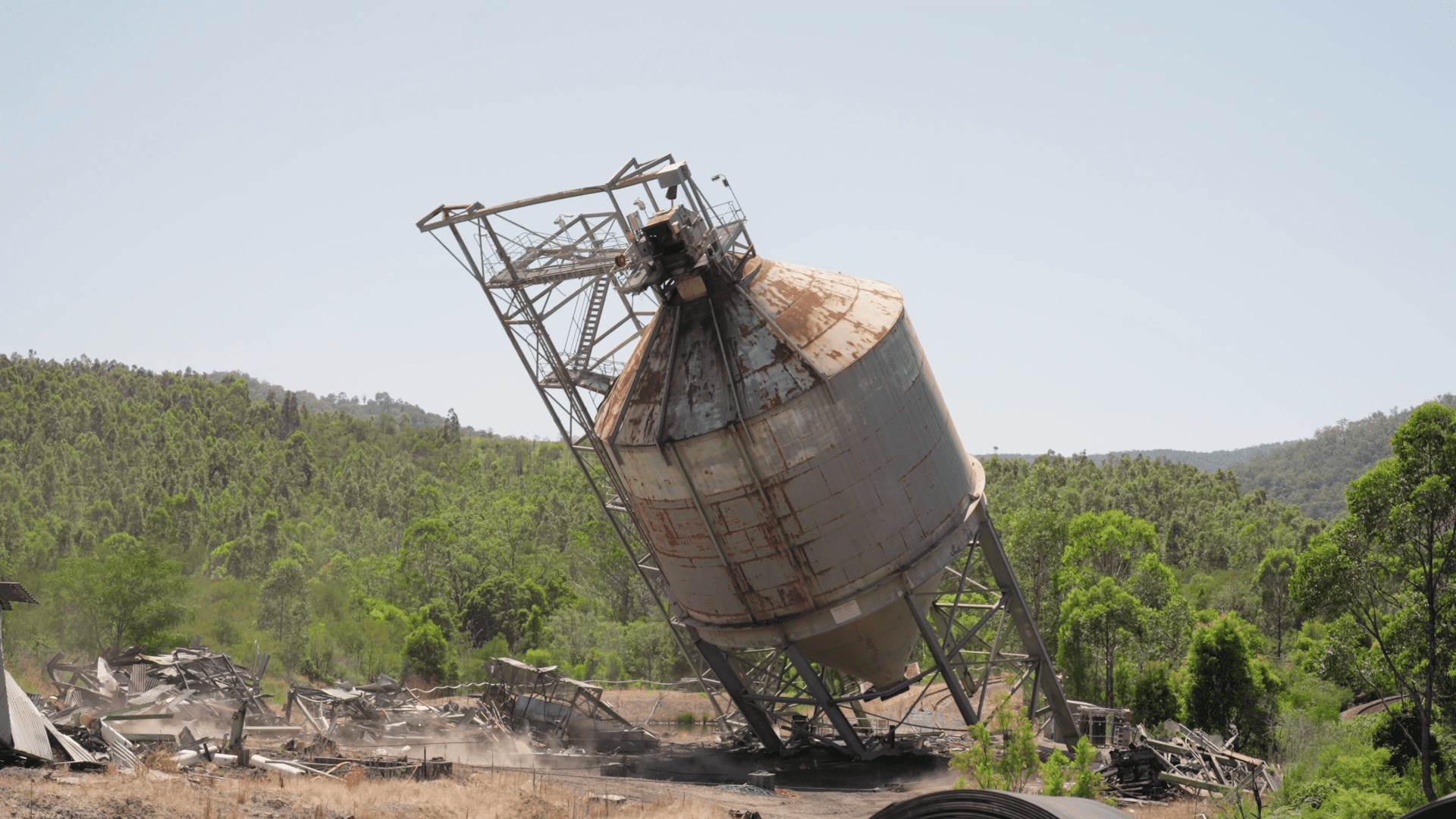

Yancoal Stratford and Duralie CHPP Demolition

Coal plant demolition

Each structure is demolished using explosive, mechanical, induced collapse and/or high-reach methods, depending on its construction, contents and clearance. Whatever techniques are used, the demolition will be completed in a controlled sequence of steps, between which another round of decontamination may be performed as required.

Throughout this process, your contractor will monitor and log every task, risk, protocol and outcome for your review. This includes all information that a plant owner, and any subsequent site owners, may need in the future, including what structures were demolished, where and how they were disposed of, which assets were scrapped and sold, what site remediation efforts took place and more.

A critical deliverable for every coal plant demolition, this meticulous documentation ensures that you have a complete record of the project after its completion.

Discover more about the general demolition process with Major Projects Group.

Site remediation and waste removal

Site remediation refers to the assessment and removal of hazardous materials after coal plant demolition. As the site owner, it is your responsibility to ensure this cleanup satisfies all regulations.

First, soil and groundwater samples should be examined for contamination. If your coal plant is beside a body of water that has been contaminated by its operations, this must be addressed as well. You will then need to devise and action an effective cleanup plan based on the investigation’s findings.

Remediation also includes determining the site’s requirements for redevelopment. Coal plants are usually situated near integral infrastructure, with easy access to transport networks, water, and fibre connection. Often, these advantages make the land highly attractive for commercial, industrial, residential and even community-focused projects, such as public parks.

With myriad technicalities to take into account, it is essential that you partner with a coal plant demolition contractor who understands how to dispose of all waste and detritus safely in accordance with the site’s next intended use.

If it is to be a greenfield site, you must replace the top several layers of dirt with fresh fill dirt, clean topsoil, seed and straw to restore it to the condition it was in before the coal plant’s construction.

Alternatively, if the property is going to be a brownfield site, then you may only be required to remediate contaminated zones. For instance, if the land will be used for housing, cleanup requirements may be more strict than if a factory were to be built, as there is less risk of direct or extended exposure to contaminants.

At Major Projects Group, we possess the specialist knowledge, permits and licences to take care of waste removal and site remediation after coal plant demolition. We can guide you through any course of action, including:

- Completely removing dismantled or demolished parts;

- Scrapping certain dismantled or demolished parts and salvaging the rest for other applications; or

- Moving dismantled or demolished parts to a new location.

A word on stakeholder management

It’s important to understand that coal plant demolition will have a significant effect on a variety of key stakeholders, from workers, neighbours and business partners to environmental organisations, government authorities and industry bodies.

Transparent, sensible and considerate consultation with these groups from the outset can help to streamline the entire process moving forward. That’s because a shared vision and open dialogue reduce the risk of future objections and other obstacles, which could otherwise delay the demolition or waste resources.

With engaged and motivated team members helping to facilitate the closure from start to finish, you will ultimately achieve a more efficient outcome.

Demolish your coal plant with Major Projects Group

Major Projects Group is proud to be a Social Enterprise leading environmental stewardship in the demolition industry. Our expert team leverages the latest equipment and certified HSEQ management systems to take care of coal plant demolitions throughout Australia.

We provide a complete range of capabilities, including decommissioning, dismantling, demolition, asset recovery and asbestos and hazardous material removal – all of which are performed with minimal impact on the surrounding people and environment.

To start your coal plant demolition with Major Projects Group, please enquire today at +61(0)2-4967-7900 or [email protected]